Our services

Range of services at a glance

The Competence Center for Processing Media (PM) in Stuttgart conducts interdisciplinary research.

We are happy to offer the following cooperative opportunities:

- Analysis of your production process

- Process data evaluation

- On-site inspection

- Sampling

- Physical, chemical and microbiological analyses of work piece, cutting tools and cooling lubricants

- Overall process analysis and derivation of optimization options

- Pre-series design and endurance tests in the Fraunhofer pilot plant, to relieve your production facilities

- Tests in biological laboratories (up to L2‑S2)

- Services

Quantitative analysis of microorganisms.

Confocal Raman microscopy for chemical, biological and mineral analysis.

Our offers in analysis and further development of cooling lubricants

- pH buffer capacity, foaming and viscosity behavior

- Chemical analysis, IR, HPLC, HPLC/MS, Raman, ICP (further information about certification/accredited testing)

- Particle analysis down to submicron scale

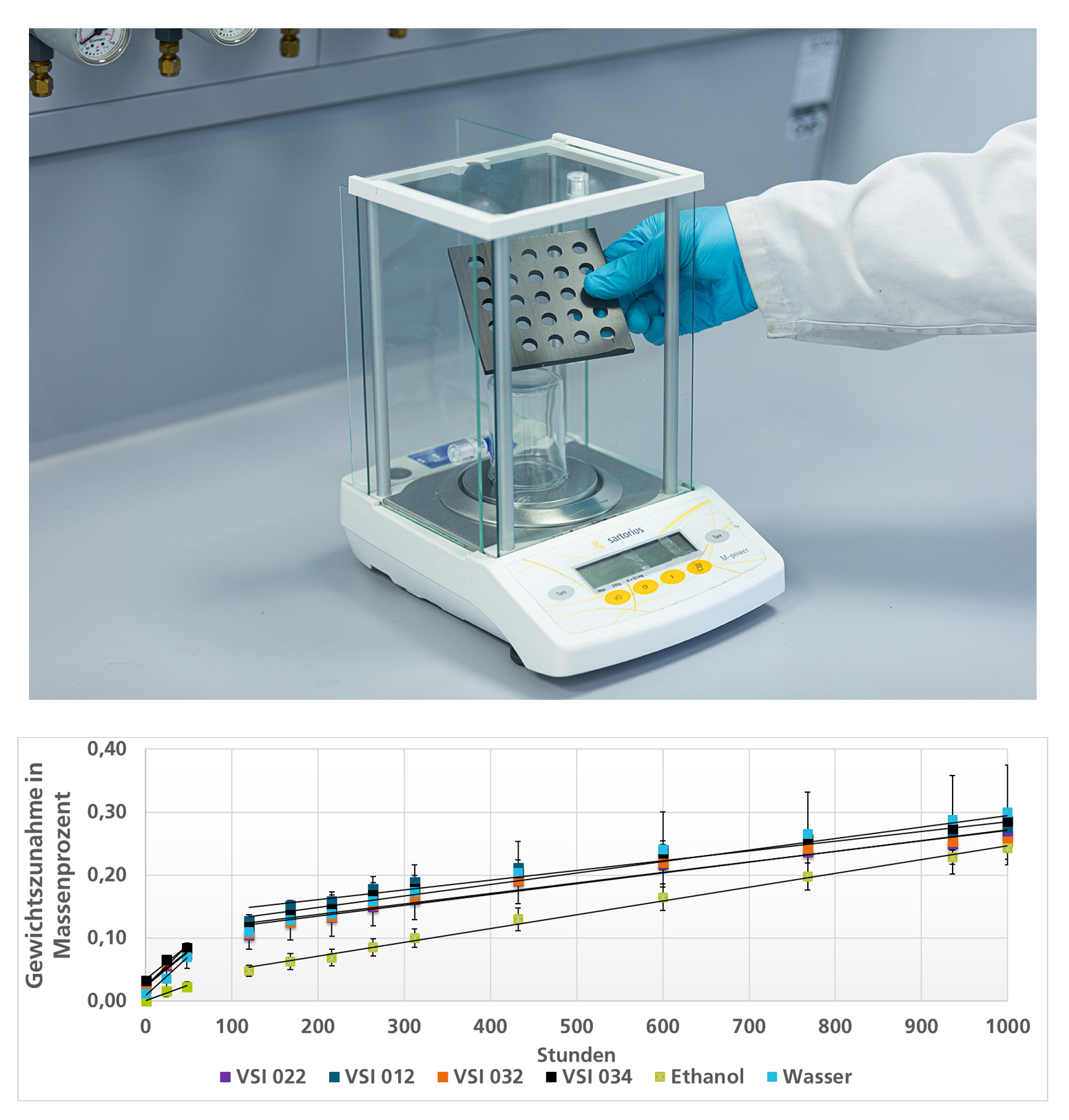

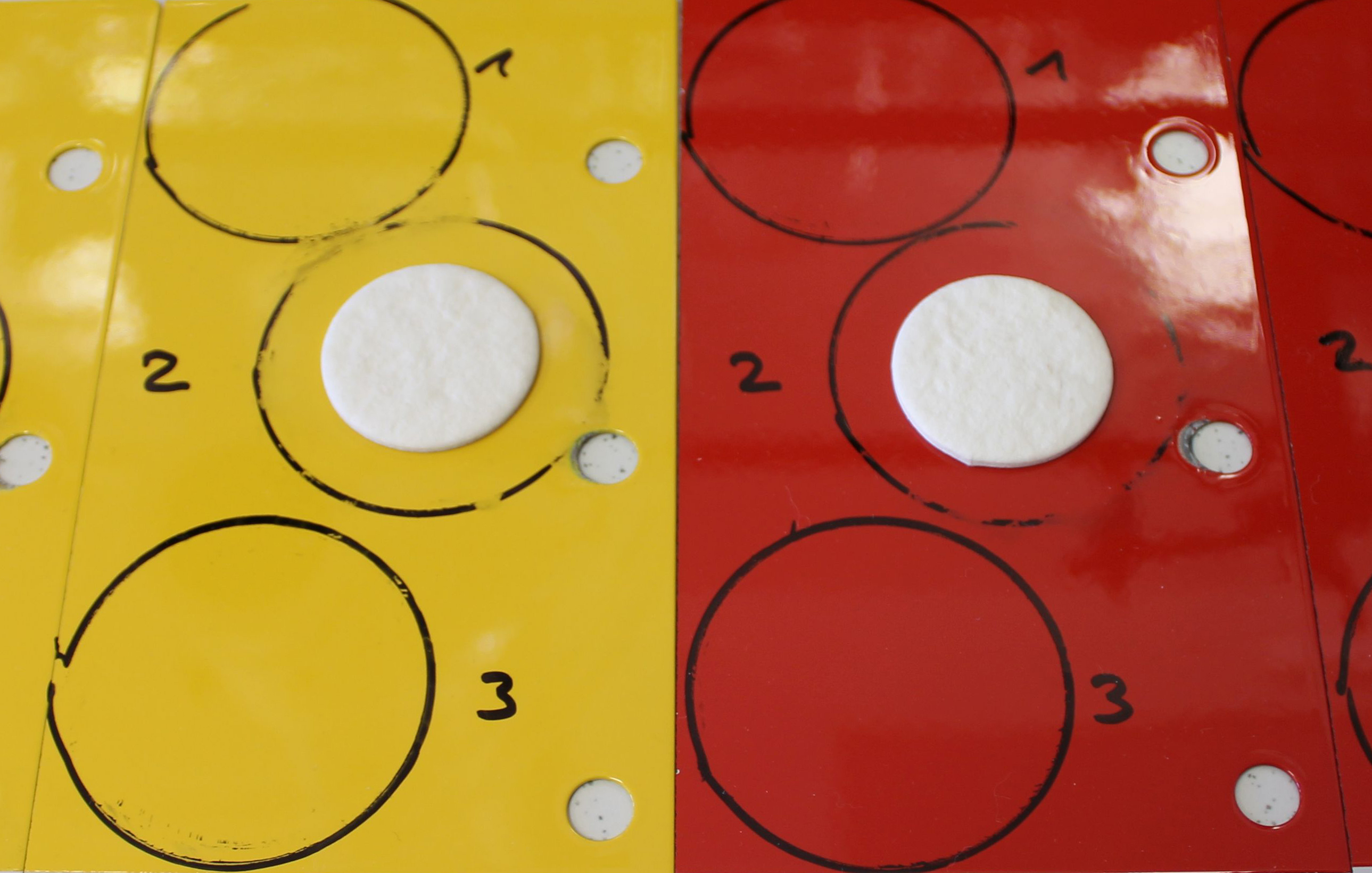

- Material compatibility testing: corrosion and resistance (work piece material, machine component material e.g. seals, pumps, pipes)

- Microbiological analysis

- Microbiological stability testing of surfaces and liquids

- Characterization and localization of microorganisms

- Microbiological monitoring and evaluation by optical systems

- Evaluation and consulting for machine cleaning and hygiene concepts

- Aging e.g. chemical transformation

Our offers in cutting process analysis

- Tool wear analysis

- Work piece quality analysis (cutting quality in benchmark test with automated image evaluation)

- Analysis and optimization of cutting parameters (rotational speed, feed rate, etc.)

- Optimization of coolant circulation and guidance, chip removal

- Filtration tests with retention rate determination

- Test bag filters, ultrafiltration filters, belt filters, ceramic filters

Our offers in cleaning and further processing

- Cleaning media, work piece swelling and chemical analyses

- Cleaning quality and determination of surface energy (test ink, contact angle measurement)

- Chemical surface cleanliness analysis

- Development of benchmark tests for cleaning, paintability and adhesiveness

- LABS (analysis for paint wetting impairment substances)

- Targeted weathering tests

- Testing and laboratory aging of painted or bonded components

Kompetenzzentrum Kühlschmierstoffsysteme Stuttgart

Kompetenzzentrum Kühlschmierstoffsysteme Stuttgart