The Stuttgart Competence Center for Processing Media (PM) for forming and machining

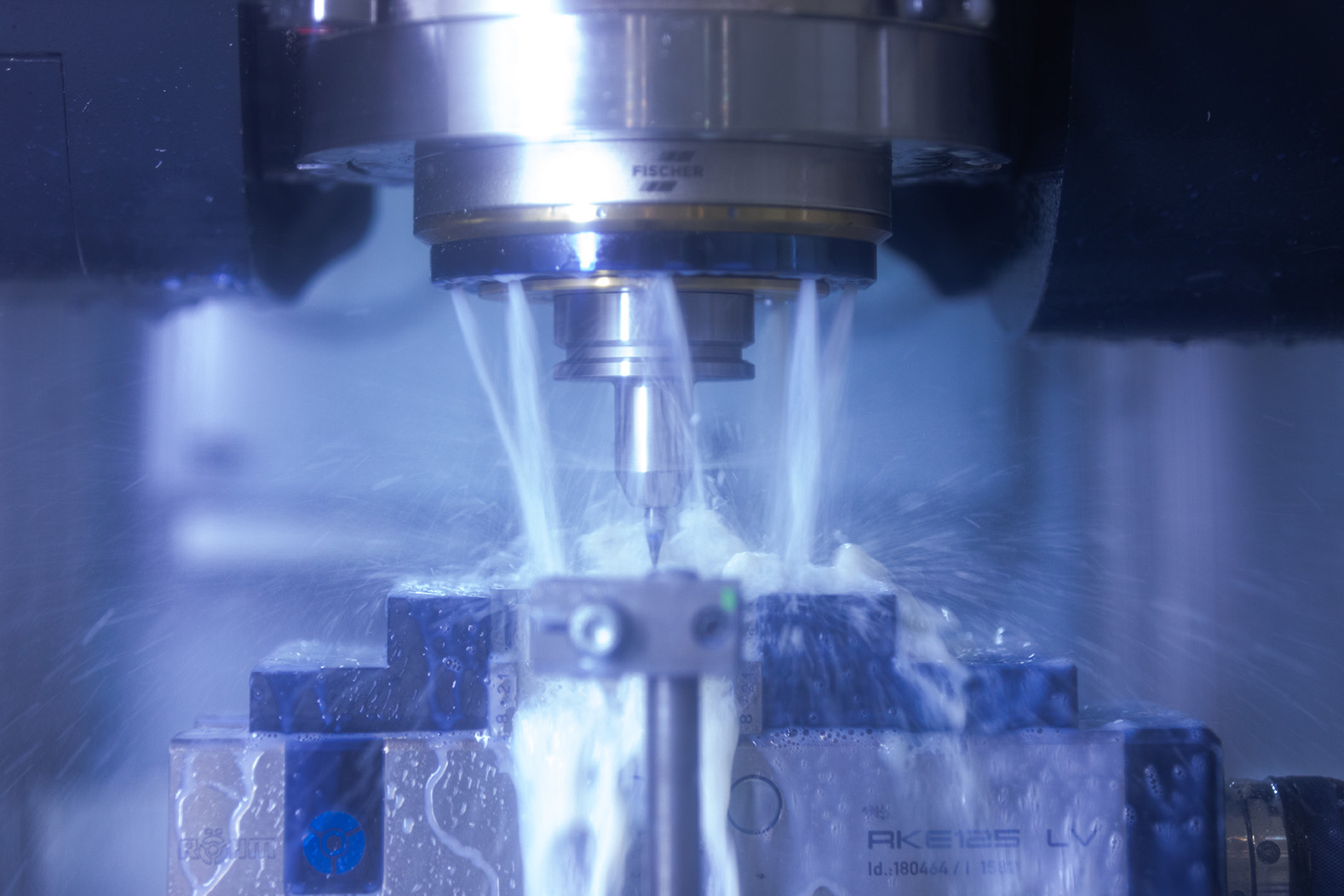

The Stuttgart Competence Center for Processing Media (PM) for forming and machining – metal working fluids, forming fluids, minimum quantity fluids, multifunctional oils – puts decades of experience at your service. We are happy to support you on analytics, maintenance and application issues.

We support both the fluid development and optimization and its operational maintenance. Optimization of cutting, milling and grinding processes may include AI supported tool and product analytics. Cleaning and subsequent painting or glueing steps are evaluated and quality assured.

Kompetenzzentrum Kühlschmierstoffsysteme Stuttgart

Kompetenzzentrum Kühlschmierstoffsysteme Stuttgart